香港創誠致佳貿易有限公司

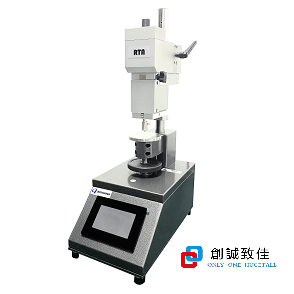

香港創誠致佳貿易有限公司一家專業從事硬度計銷售、選型及方案定制服務商,提供橡膠硬度計的報價和測試方案,主營產品有硬度計、···

動態文章

二氧化碳培养箱是通过在培养箱箱体内模拟形成一个类似细胞/组织在生物体内的生长环境,培养箱要求稳定的温度(37°C)、稳定的CO2水平(5%)···

Posted in 技術文章 by Admin on 2023-10-12 16:50:15

拋光是通過摩擦或應用化學處理來創建光滑且有光澤的表面的過程,留下具有顯著鏡面反射的幹淨表面。在某些材料(例如金屬、玻璃、黑色或透明石頭)中,···

Posted in 技術文章 by Admin on 2023-10-10 10:03:32

硬度壓頭是硬度計上壓入試件而無**變形的零部件。常用的硬度壓頭有洛氏硬度壓頭、布氏硬度壓頭、維氏硬度壓頭、努氏硬度壓頭以及一些硬度計壓頭等。

Posted in 技術文章 by Admin on 2023-10-09 17:14:07

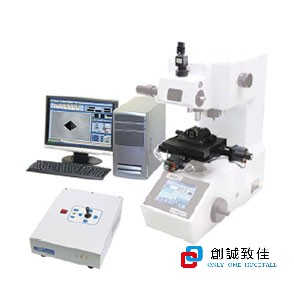

奧林巴斯創立於1919年,至今已經有一百多年。奧林巴斯是一家精密光學與成像的日本公司,以顯微鏡事業起家。顯微鏡的透鏡研磨技術被譽為“獨門秘笈···

Posted in 技術文章 by Admin on 2023-10-08 11:40:31